- Information

- About Us

- Service and Warranty

- Delivery and payment

- News

- Contacts

- АКЦИИ

Corn sugar is one of the important ingredients needed to make beer. For the normal course of fermentation, sugar made from other types of raw materials is suitable - cane, beet. In brewing, different types of similar additives are used - glucose, fructose, sucrose, maltose and others. For example, the dextrose in beer is crystallized glucose.

The main share of sugar is extracted from malt in a natural way. Additionally, sugar is introduced into the malt to speed up the fermentation process or to adjust the taste characteristics of the beer. Corn and cane sugar, as well as substitutes, play an important role in the preparation of the drink. By choosing different types of sugar, you can adjust the taste and other characteristics of beer, for example:

- Increase the strength of the drink, leaving the density indicators at the same level.

- Reduce the density of the drink, keeping the strength indicators at the same level.

- Get new taste nuances.

For example, white candy sugar is traditionally used to make high-strength Belgian ales. This type of sugar contributes to a light consistency and increased strength of the drink. When using cane or beet sugar, there is a high probability of unpleasant flavors appearing, which is due to the content of impurities in unrefined raw materials. Brown sugars give the beer a caramel flavor.

Corn sugar, dextrose and other types of fermentants are suitable for making beer. However, dextrose gives better results in the form of increased speed of preparation of alcoholic beverages and impeccable taste characteristics. For example, beer brewed with dextrose does not have a pronounced sweetish aftertaste, as is often the case if sugar is present in the malt composition.

Dextrins are oligosaccharides that are formed as a result of the breakdown of starch contained in malted grains. Today, manufacturers offer ready-made dextrose as a sugar substitute. Yeast fungi that support the fermentation process are fed by fructose and glucose. These components are formed from sucrose by the action of enzymes. As a result of fermentation, beer glucose and fructose are converted into ethyl alcohol and carbon dioxide.

Benefits of Using Corn Dextrose

Corn dextrose helps to speed up the preparation of the drink and reduce the content of foreign substances - by-products. It takes longer to convert sucrose into nutritionally acceptable forms than dextrose. As a result of multiple chemical transformations in beer wort prepared on the basis of sucrose, in addition to ethyl alcohol and carbon dioxide, other products are formed - fusel oils, hydrocarbons and esters, aldehydes, organic acids and higher alcohols.

All these components affect the taste and aroma characteristics of the finished beer. If cane or corn dextrose is used instead of sucrose, the amount of by-products and their volume fraction in the beer are reduced to zero. The result is an improvement in the taste properties of beer, neutralization of extraneous flavors, including the absence of the taste of fusel oils. Corn dextrose is also used for the preparation of distillate, strong alcoholic beverages.

Due to the absence of additional chemical reactions associated with the conversion of sugar into glucose and fructose, whiskey wort fermentation is faster. Dextrose speeds up the fermentation process. Alcoholic drinks based on it do not leave an extraneous aftertaste. On the other hand, with the help of different types of sugar, you can create unique products with a rich originality of flavors. If you are thinking about where to buy dextrose in beer, Prolitech LLC will help you to cope with the task.

Where to buy dextrose in beer

Prolitech LLC offers to buy Castle Malting caramel sugar (Belgium), fructose and dextrose in beer. If you decide to order goods in the online store, save money and time. You can apply without leaving your home or office. The procedure takes several minutes. Why is it profitable to cooperate with our company:

- We will quickly deliver the ordered goods to cities in Ukraine - Kiev and Dnipro, Kharkiv, Odessa, Lviv, Mariupol, Krivoy Rog, Zaporozhye.

- Affordable price for products of manufacturers with a worldwide reputation.

- Professional advice, assistance in the selection.

We equip food industry enterprises with equipment, raw materials, containers for storage and transportation of food and beverages. We will install and configure the equipment. Our customers are guaranteed consulting support and service.

Wort clarifiers, brewing sugar, enzymes

-

-

-

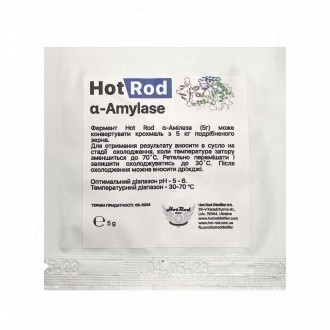

code: 16185from 55 UAHAvailable in stock

-

-

-

-

-

-

-

-

code: 16857from 83 UAHAvailable in stock

-