Full cycle home cheese dairy for 30 l. Automatic cheese dairy with stirrer and whey drain.

Automatic, tabletop cheesemaker-pasteurizer for 30 l. milk (total volume 32 l.) Designed for preparing cheeses of varying complexity, kefir, yoghurts at home. Full cycle cheese factory 30 liters made by a cheese maker for cheese makers!

With the help of a 30-liter mini cheese factory, you can prepare the most famous cheeses in the world at home.

A cheese factory-pasteurizer allows you to perform the following processes for preparing cheese at home: heating milk, pasteurizing milk, ripening and increasing the acidity of milk, ripening curds (fermentation), slicing curds (using Lyra) horizontally and vertically, placing grain, kneading and drying grain (with using a mixer with automatic reverse and speed control), draining the whey and forming a cheese layer, filling molds in bulk (using a drain tap), you can also carry out stufaturation and chederization of a head of cheese and cook ricotta.

The cheese factory is available in two options.

1 - Cheese plant with stirrer controller and temperature controller

2. Cheese factory with a new automatic controller with a touch screen with automatic cooling function. The valve is included only when ordering a new controller.

The presence of a new cheese factory control controller with a touch screen allows you to easily and conveniently monitor and manage the cheese preparation process at all stages. The new temperature sensor with a PT100 platinum element will allow you to maintain the temperature in the cheese making bath with an accuracy of 0.1 C, while the controller controlled by the STM3000 microprocessor, which works according to the PID control protocol, will allow you to maintain the set temperature in the cheese factory, without inertia.

The ability to adjust the mixer speed from 0 to 30 revolutions per minute, as well as turn on the reverse of the cheese grain mixer and change the time when the reverse is turned on, allows you to knead and dry the cheese grain in conditions as close as possible to industrial ones. This will save you from the long procedures of kneading grain by hand and free up time for household chores while your cheese is being prepared.

The built-in timer will notify you with a sound signal about the end of time for a particular procedure for preparing cheese at home.

Convenient lyres, made similar to industrial knives, for cutting cheese curds allow you to quickly cut the cheese curd and place the grain without resorting to additional knives.

Using a half-bottom drain valve and a whey drain, you can drain part of the whey from the tabletop cheese factory to carry out the grain deoxidation process, drain all the whey for further work with cheese grain, and also fill cheese molds using the pouring method, if this is provided for by the procedure preparation of this type of cheese.

The built-in heating element of the cheese factory is made of stainless steel, which makes its service life practically unlimited.

Having a cheese book will allow you to retain the cheese grain without loss when draining the whey. You achieve a result when all the grain remains in the cheese factory and you can safely continue to work with it. Carry out salting, filling molds, forming a layer and much more.

The body of the cheese factory, made of stainless, non-magnetic food steel AISI 304, 1.5 mm thick, makes the home cheese factory completely suitable and safe for preparing any food products in an aggressive environment (the acidic environment of cheese whey) and also has a huge margin of safety, which makes the service life of a home mini cheese factory practically unlimited.

Please note that Pervachenko's cheese factories are constantly being modernized, we do not always have time to change the information in the instructions and on the website, so your cheese factory may be slightly different from the one you see in the photo, and have new improvements and enhancements.

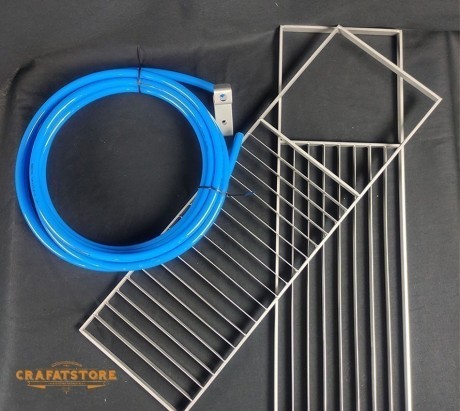

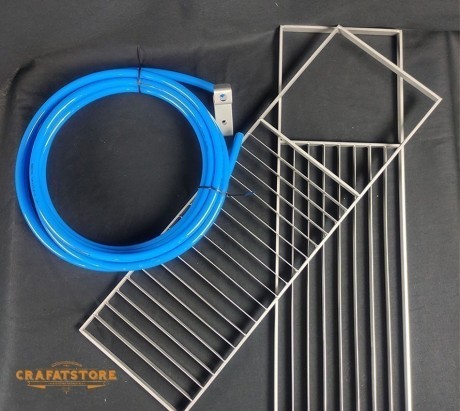

Contents of delivery:

Cheese making bath with a capacity of 32 liters. - 1 PC

Legs for cheese dairy – 4 pcs.

Ball valve 1 inch – 1 pc. (in models with whey drain)

Drain 1 inch – 1 piece

Quick cut – 2 pcs.

Stirrer – 1 piece

Cover consisting of 2 halves – 1 pc.

Normally closed solenoid valve – 1 piece (in the version with sensor automation)

Clip for thermometer - 1 pc.

Heating element (3 kW) - 1 piece

Process control unit – 1 piece (customer’s choice)

Clamps and gaskets in the required quantity for assembly.

Lyre, for cutting curd - 2 pcs.

Cheese book - 1 pc.