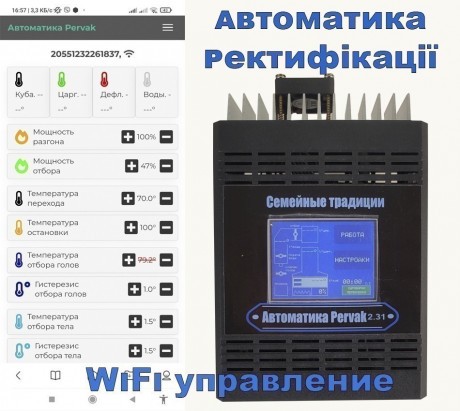

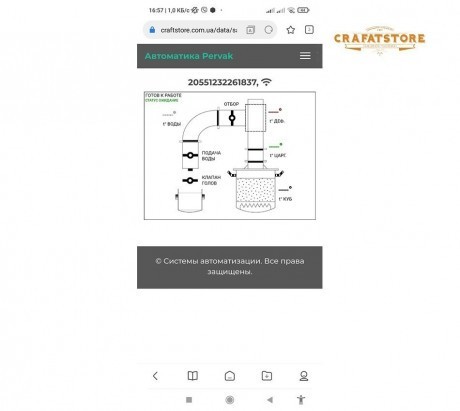

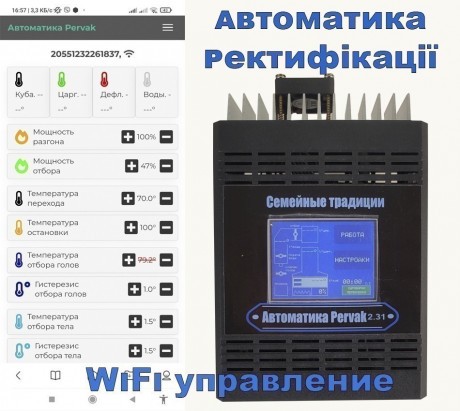

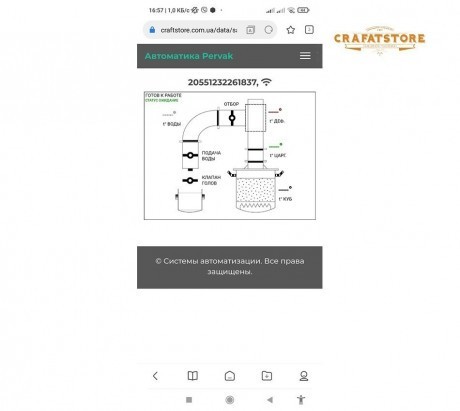

Pervak 2.6 automation with a web interface is a new generation controller. With the help of automation for rectification, you can fully automate the processes of distilling mash into raw alcohol, automation of rectification, automation of brewing, automation of mashing. Automation for rectification allows you to control all processes remotely, from a smartphone or computer, using an application or web interface.

Basic operating modes of automation for moonshine brewing:

- Distillation (processing mash into raw alcohol in potstill mode)

- Rectification with liquid selection

- Mashing or brewing beer (up to 10 temperature pauses and cooling with a chiller)

- In manual mode, automatic rectification can be used to control the following processes: Heating element power adjustment, Precise temperature maintenance in PID mode, Emergency stop of the system due to water flow, cube overheating and TSA temperature increase, Precise control of the selection speed and control of selection valves, heads and supply of cooling water, Temperature control in the cube, drawer, selection unit and TSA.

Automation for distillation, rectification and mashing allows you to fully automate the process of distilling mash into raw alcohol, the rectification process, the process of brewing beer and mashing grains for whiskey and bourbon.

The Wi-Fi module provides you with complete control and management of all automatic distillation processes. All you need is to connect the controller to a stable source of Internet connection and have access to the network on your smartphone.

Information synchronization time is 15 seconds.

When using the Pervak Application browser, you can receive push notifications about automation processes and errors.

The automation is designed to control heating elements or electric stoves with a power of up to 3.5 kW, which is quite enough for most processes carried out at home.

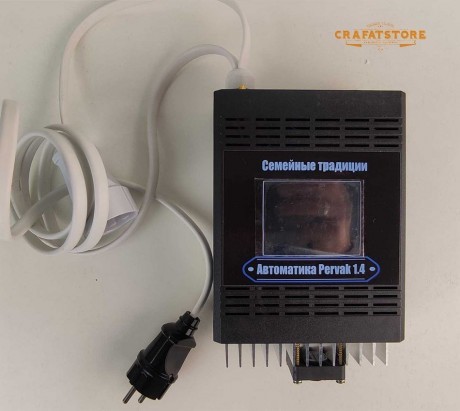

For ease of use, the controller is equipped with a DIN rail for wall mounting.

The delivery set of Automation for Distillation, Rectification and Mashing Pervak 2.6 Wi-Fi includes:

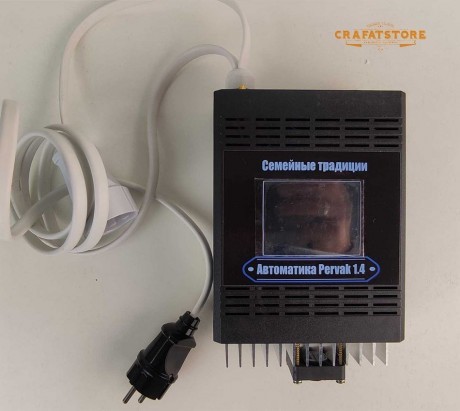

Automation with touch screen 1 pc.

Block dimensions Height 70 mm; Width 140 mm; Length 220 mm.

Solenoid valve 3 pcs. Cable length 2 meters

Temperature sensor 4 pcs. Cable length 2 meters

Level sensor 1 pc. Cable length 2 meters

Tee for head valve for 10 mm hose. 1 PC.

Tee for water temperature sensor 1 pc.

Quick release 0.25 for 10 mm hose 6 pcs.

Nipple for thermometer sensor 1 pc.

Operating modes

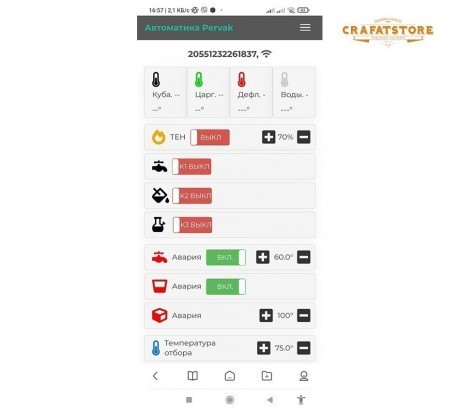

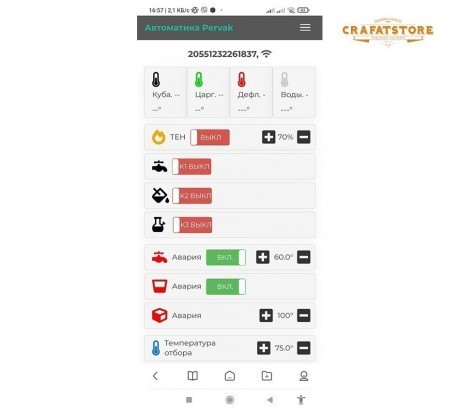

In Manual mode you can:

- manually turn on and off the heating element or electric stove

- adjust the power of the heating element

- maintain accurate temperature in PID control mode

- open and close the water supply valve

- open and close the extraction valve

-set temperature, hysteresis and sampling rate as a percentage

- set the Emergency mode for water, level and cube temperature

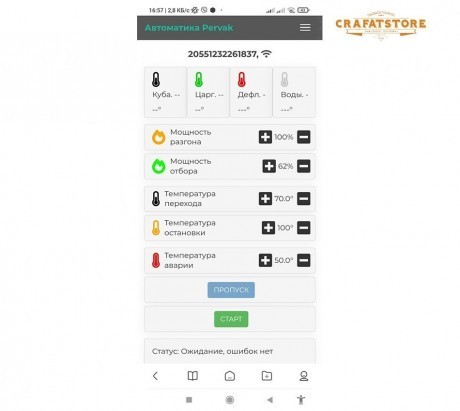

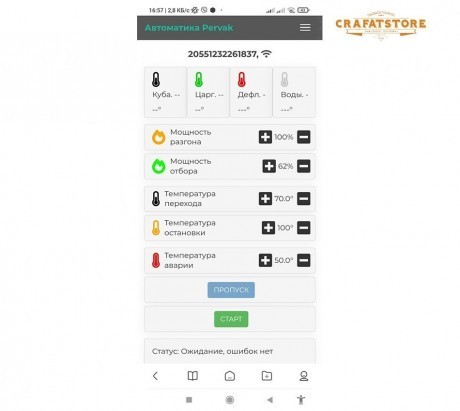

In Distillation mode you can set:

- acceleration power

- selection power

- temperature of transition from maximum power to extraction

- stop temperature

- water accident temperature

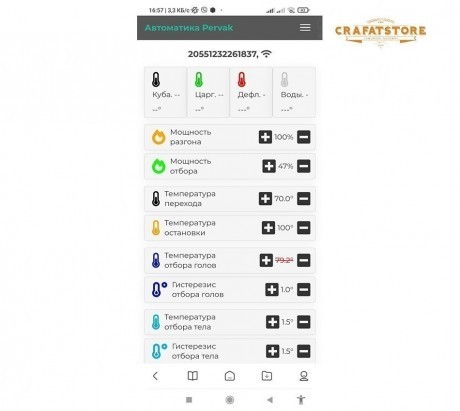

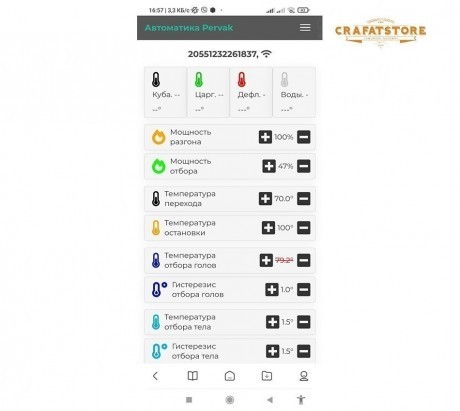

In Rectification mode you can specify:

- acceleration power

- work power

- operating temperature (in the drawer)

- stop temperature per cube

- temperature of head selection (set automatically after stabilization of the column)

- goal selection hysteresis

- body selection hysteresis

- speed of goal selection

- body selection speed

- water accident temperature

- column stabilization time

- number of start-stop cycles

- reducing the selection, upon reaching a certain temperature in the cube, to maintain the reflux ratio.

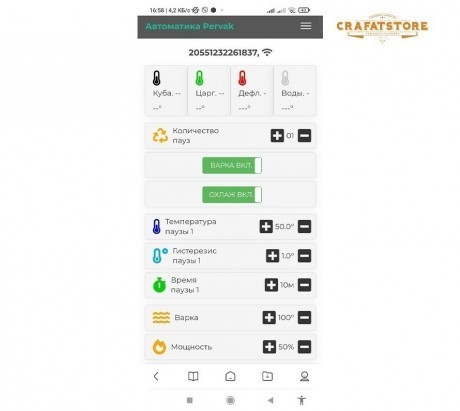

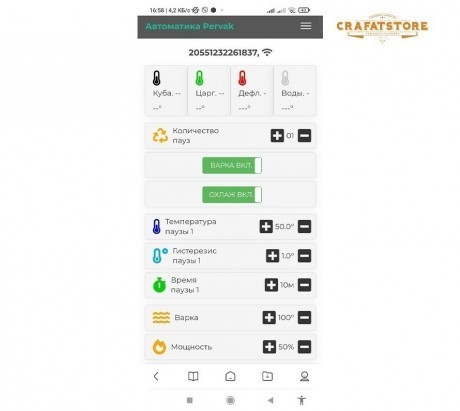

In the Mashing mode you can:

- indicate the number of temperature pauses

- turn cooking on or off

- turn cooling on or off

- for each pause you can select the temperature, hysteresis